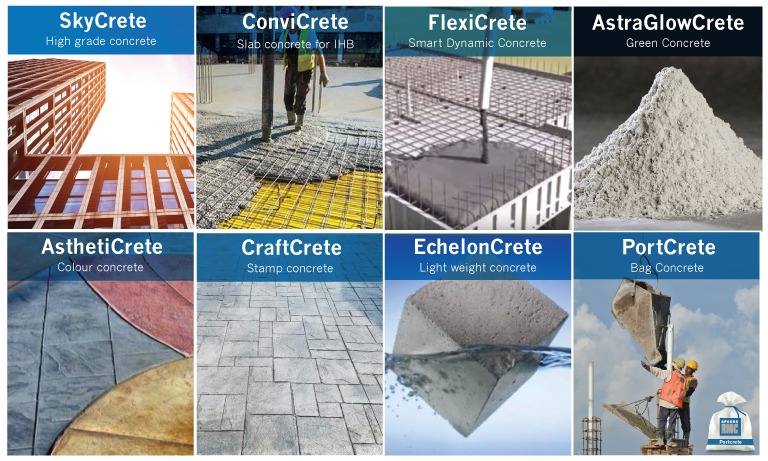

9 Types of Specalised Ready Mix Concrete you didn’t know existed

December 18, 2023

Concrete, a cornerstone of construction, is more diverse than you might think. Beyond the traditional mix, a world of concrete types exists, each with its unique purpose and significance. Whether you’re a construction professional seeking precision or an enthusiast curious about the possibilities, this blog will be your comprehensive guide to the types of specialised ready-mix concrete you might not have known existed.

In the following sections, we will explore nine remarkable specialised ready-mix concrete variants redefining the construction industry with their distinct properties and applications.

1. High-Grade Ready Mix Concrete:

High-grade RMC, often known as ultra-high-performance concrete (UHPC), showcases remarkable engineering. It is meticulously designed to be incredibly strong and long-lasting, making it ideal for the most challenging projects. Imagine sturdy bridges spanning wide rivers, dams withholding a large water reservoir, and industrial buildings enduring harsh weather conditions. High-grade ready-mix concrete excels at withstanding the test of time and nature’s most demanding challenges.

2. High Volume Fly Ash / GGBS Concrete:

High-volume fly ash or ground granulated blast furnace slag (GGBS) RMC is an excellent eco-friendly option. By adding fly ash, or GGBS, to the mix, this ready-mix concrete reduces its carbon footprint and proves to be cost-effective.

GGBS concrete fits well with the growing interest in environmentally friendly construction. As the construction industry increasingly leans toward greener practices, high-volume fly ash/GGBS mixed concrete is at the forefront of this shift towards a more sustainable future.

3. Coloured Concrete:

Ready mix concrete has transformed, shedding its traditional grey appearance to embrace vibrant colours. Coloured RMC offers a wide range of hues, emphasising the growing importance of aesthetics in construction projects. It adds a creative dimension to applications like decorative surfaces, landscaping, and architectural elements.

Beyond functionality, coloured concrete plays a significant role in elevating the visual appeal of structures, showcasing the harmonious blend of form and function in construction.

4. Stamped Concrete:

Stamped concrete is a specialised technique that replicates the appearance of natural materials like stone, brick, or wood on a concrete surface. It involves adding patterns, textures, and often colours to freshly poured mixed concrete before it sets. This process creates a visually appealing and, textured finish that closely resembles the chosen natural material.

The applications of stamped concrete are diverse and versatile. It’s commonly used for various outdoor and indoor projects. For outdoors, it’s ideal for driveways, patios, walkways, and pool decks, which enhance aesthetics and provide a durable surface. It can be used indoors for flooring in areas like basements, commercial spaces, and even residential interiors.

The versatility of stamped RMC lies in its ability to combine the attractive appearance of natural materials with the durability and affordability of ready-mix concrete.

5. Lightweight Ready Mix Concrete:

When weight is a concern, lightweight concrete becomes a viable solution. It possesses properties that make it significantly lighter than traditional ready-mix concrete without compromising on strength. Beyond its weight advantage, it offers improved insulation properties, reducing energy consumption and lowering the structural load. This versatility makes it an excellent choice for various construction applications, particularly in situations where weight considerations are paramount.

6. Slab Concrete for IHB (Industrial Heavy-Duty Flooring):

Slab concrete, also known as industrial heavy-duty flooring, is a specialised flooring solution tailored for demanding industrial environments. Its exceptional characteristics, such as its ability to withstand heavy loads and resist wear and tear, make it an essential choice for places like factories, warehouses, and other high-traffic areas.

In practical terms, RMC slab concrete is like the superhero of floors in these settings. It can bear the weight of heavy machinery, endure constant foot traffic, and resist damage from various sources. This reliability is crucial because it ensures the longevity and durability of the flooring in places where standard ready-mix concrete would wear out quickly. Ultimately, slab concrete contributes to safer and more efficient operations in these industrial settings.

7. Self-Compacting Concrete (SCC):

Self-compacting concrete (SCC) is a remarkable building material that can place itself without the need for manual vibration. It achieves this through a precisely balanced mix of fine materials, powders, and superplasticisers, allowing it to flow and level autonomously.

SCC stands out for its labour-saving qualities. It eliminates the need for manual vibration, streamlines construction processes, reduces costs, and minimises the potential for errors. SCC ensures consistent quality and uniform concrete distribution in various construction scenarios, making the work easier for builders and engineers.

8. Steel Fiber Reinforced Concrete (SFRC):

Steel Fiber Reinforced Concrete (SFRC) is a type of ready-mix concrete that gains its strength from the addition of small steel fibres to the mix. These steel fibres act like reinforcements, making the concrete more resistant to cracking and improving its ability to withstand stretching and pulling forces.

SFRC has various mechanical properties making it a preferred choice for various applications, such as industrial flooring, tunnel construction, and buildings in earthquake-prone regions. Its exceptional ability to absorb energy and resist cracking under stress makes it a dependable and cost-effective solution for challenging environments. In essence, SFRC is like giving your ready-mix concrete an extra layer of resilience, ensuring it performs well in demanding situations where regular mixed concrete might fall short.

9. Bag Concrete

Bag concrete, often known as “concrete in a bag,” is a prepackaged concrete mix that combines cement, sand, and aggregate in convenient bags. This pre-mixed concrete simplifies the mixing process, making it a popular choice for DIY enthusiasts and professionals. Bag Concrete ensures consistent quality and eliminates the need to measure individual components, saving time and reducing the risk of mixing errors. It is available in various bag sizes, making it easy to purchase the right amount for specific projects and minimising waste.

Bag concrete is used in a wide range of construction activities, from setting fence posts and anchoring fixtures to small-scale repairs, patching, and creating foundations for garden walls or deck posts. It is a handy solution for quick and limited-volume projects, providing a convenient way to work with concrete for various construction and repair needs.

Aparna RMC

Aparna RMC’s ability to offer specialised ready mix concrete solutions, whether it’s the strength and durability of high-grade concrete for challenging structural needs, the aesthetic appeal of coloured concrete, or the efficiency of self-compacting concrete, makes them trusted partners in your construction endeavours.

As trusted partners, Aparna RMC guides and assists you every step of the way, ensuring that the right ready-mix concrete type is available, precisely when and where it’s needed. Aparna RMC’s unwavering commitment to on-time delivery and top-quality production further reinforces its position as the leader in the construction industry, offering a dynamic palette of concrete solutions to make every project a success.