The Future of Concrete: 5 Emerging Trends and Technologies

May 15, 2025

Concrete has long been the foundation of modern infrastructure, from towering skyscrapers to expansive highways. But as the world shifts towards more sustainable, efficient, and technologically advanced construction practices, concrete, too, is undergoing a major transformation. Driven by environmental concerns, digital innovation, and the demand for high-performance materials, the future of concrete looks smarter, greener, and more adaptable than ever before.

In this blog, we explore the key trends and technologies shaping the future of concrete and how these changes are redefining the way we build.

1. Sustainable and Low-Carbon Concrete

The environmental cost of traditional concrete production—especially from Portland cement—is significant. Emerging solutions are now targeting carbon neutrality and resource efficiency.

Key Developments:

- Supplementary Cementitious Materials (SCMs) like fly ash, GGBS, and silica fumes replace a portion of cement, reducing CO₂ emissions while enhancing durability.

- Geopolymer Concrete made from industrial by-products offers up to 80% lower carbon emissions.

- Recycled Aggregates minimize natural resource depletion and support a circular economy.

- Carbon Capture Technologies injects CO₂ into fresh concrete to both sequester carbon and improve material properties.

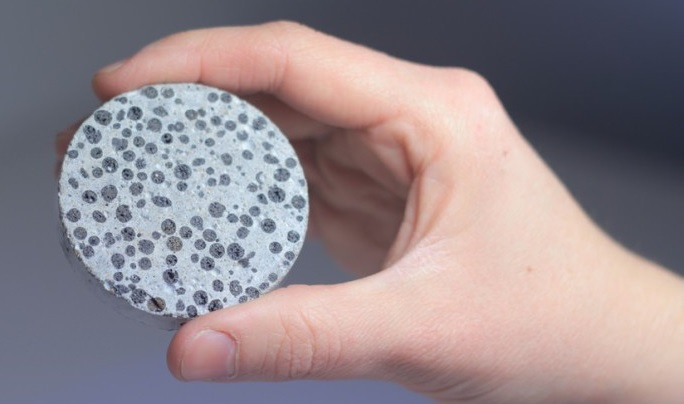

2. Smart and Self-Healing Concrete

Imagine a concrete that repairs its own cracks, or monitors its own condition in real time. These are no longer futuristic ideas, but emerging realities.

Innovations to Watch:

- Self-Healing Concrete using bacteria or microcapsules to automatically seal cracks when moisture enters.

- Smart Concrete embedded with sensors to track temperature, stress, and humidity, helping to predict and prevent structural failures.

- High-Performance Concrete (HPC) designed for extreme loads and harsh environments with enhanced strength, ductility, and longevity.

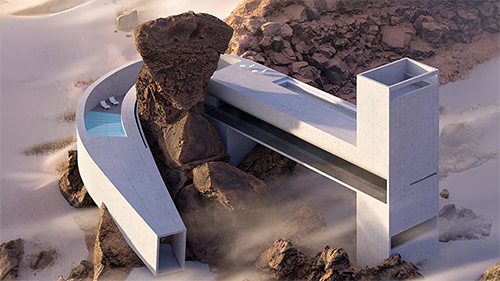

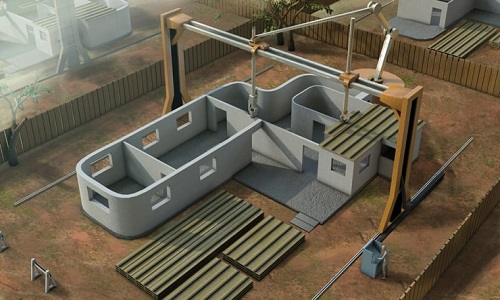

3. 3D Printing and Modular Construction

Concrete is entering the era of digital fabrication. 3D concrete printing is enabling faster, cost-effective, and customized construction methods.

Benefits:

- Complex designs are produced with precision and minimal material waste.

- Faster project timelines through off-site prefabrication and modular assembly.

- Better quality control in factory environments compared to on-site work.

4. Advanced Concrete Mix Designs

Concrete mix design is no longer a trial-and-error process — it’s being revolutionized by nanotechnology and data science.

Cutting-Edge Trends:

- Nanomaterials like nano-silica and graphene oxide enhance strength, reduce permeability, and extend service life.

- Intelligent Admixtures improve workability, setting time, and resistance to environmental stress.

- AI and Machine Learning optimize mix proportions and predict performance, reducing material wastage and human error.

5. Ultra-High Performance and Specialty Concretes

Concrete is not just about compression strength anymore. It now caters to architectural freedom, extreme durability, and new functional features.

Emerging Materials:

- Ultra-High Performance Concrete (UHPC) exceeds 200 MPa in compressive strength, with exceptional durability.

- Light-Generating Concrete absorbs sunlight and emits light, ideal for roads and public spaces.

- Translucent Concrete integrates fiber optics to allow light transmission, transforming architectural aesthetics.

The Road Ahead: Greener, Smarter, Stronger

Concrete’s evolution is a response to urgent global demands — for resilience in climate-challenged environments, for faster and smarter urban development, and for reduced environmental impact.

As digital tools and sustainable materials continue to disrupt traditional methods, concrete will play a central role in building the infrastructure of the future — one that’s stronger, more efficient, and aligned with a net-zero vision.

Why Aparna RMC Is Leading the Future of Concrete

At Aparna RMC, innovation is more than a buzzword — it’s at the core of everything we do. We are constantly evolving our concrete solutions by integrating:

- Eco-friendly mix designs using SCMs and recycled materials

- Advanced batching technologies for precision and consistency

- On-site and laboratory testing protocols aligned with IS and global standards

- Customised high-performance mixes for critical infrastructure, real estate, and industrial needs

With a strong presence across South and West India and a proven track record in delivering excellence, Aparna RMC stands at the forefront of the concrete revolution — helping build tomorrow’s structures with today’s smartest solutions.Connect with Aparna RMC — where sustainability, performance, and technology converge.